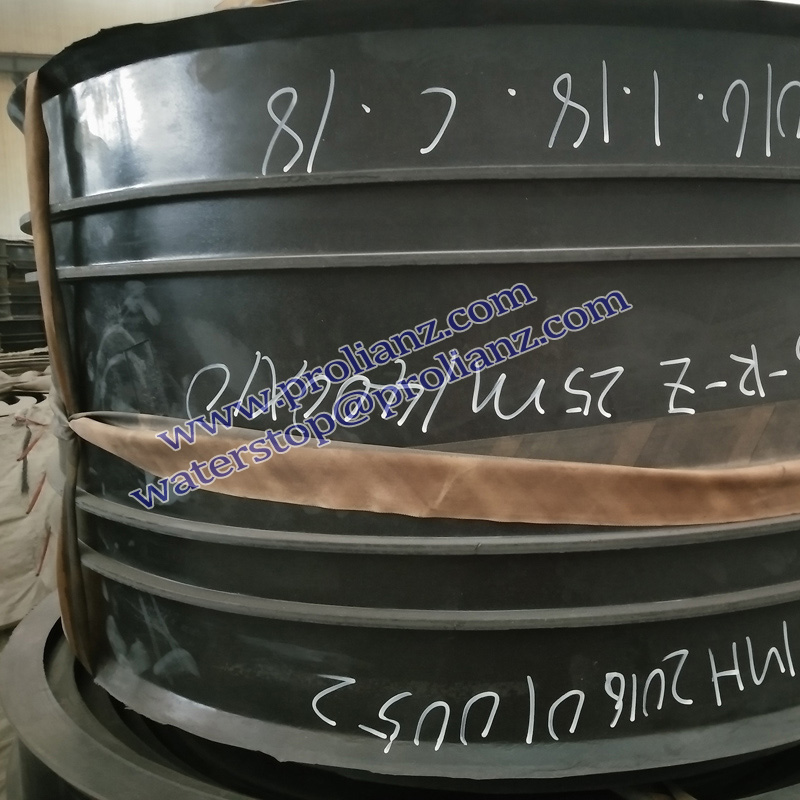

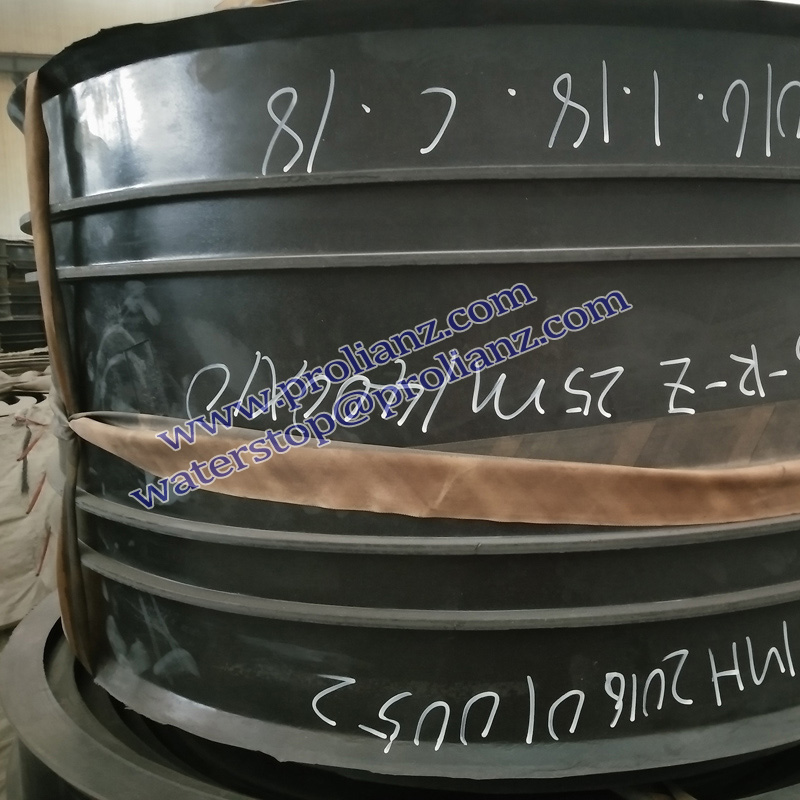

Model NO.: various Ceiling Tile Shape: Rectangle Thickness: 4.0mm Surface Treatment: Roll Coated Certification: ISO Usage: Outdoor Trademark: JianFeng Origin: Hebei, China Type: Building Sealing Material Material: Rubber Ceiling Tile Type: Rubber Function: Waterproof Color: Black Certificate: ISO9000 Specification: As Drawing Requests HS Code: 5522233 Contact information

Sales Manager: Miss Anna Lee

Mobile Phone: +86-15132836877

Tel: 86-318-5106277

Fax: 86-0318-5106277

Website: www.prolianz.com

Company: Hengshui Jianfeng Engineering Rubber co., LTD.

Description of

Rubber Water StopRubber waterstop, made of quality SBR (styrene butadiene rubber),

neoprene rubber or natural rubber, is one of the widest types for

concrete structure to prevent liquid leaking in or out. Generally,designed

to be cast in the concrete, rubber water stops are ideal for applications

where high physical properties of rubber are required. For example,

reservoirs, dams and other water retaining or excluding applications with

high movements or water pressure.

Description index of rubber

Water Stop | Description | Index |

| 1. Hardness ( Shore A ) | 60±5 | 60±5 | 60±5 |

| 2.Tensile strength ,MPa ≥ | 15 | 12 | 10 |

| 3.Elongation at break , % ≥ | 380 | 380 | 300 |

| 4.Compression set % | 70°×24h,

% ≤ | 35 | 35 | 35 |

23°×168h,

% ≤ | 20 | 20 | 20 |

| 5. Tear strength ,KN/m ≥ | 30 | 25 | 25 |

| 6.Brittleness temperature, ≤ | -45 | -40 | -40 |

7.Hot air

aging | 70°×

168h | Hardness (shoreA) | +8 | ------ | _ |

Tensile strength,

MPa ≥ | 12 | 10 | _ |

Elongation at

break, % ≥ | 300 | 300 | _ |

100°×

168h | Hardness (shoreA) | __ | __ | +8 |

Tensile strength,

MPa ≥ | __ | __ | 9 |

Elongation at

break, % ≥ | __ | __ | 250 |

8. Resistance to ozone ageing

50pphm:20%,48h | Grade2 | Grade2 | Grade0 |

| 9. Adhesion of rubber to metal | With contact section in elastomer |

| 10. Notes | (1) Adhesion of rubber to metalis used

to the rubber water stop with steel edge.

(2) If there are other special requirements,

it could add inspection items properly

after making deal by both sides.When as

users'requirements to check mildew test

according to the circumstances, the

mildew proof property must be equal to

or over Grade 2. |

Features of rubber water stop

High elasticity.

High elongation.

Excellent high movement accommodation.

Capable to withstand high hydrostatic head.

Adjust for subsidence and seismic movements.

Hot vulcanized site joints.

Applications of rubber water stop

Ideal for high movements joints.

Water containments.

Water excluding.

Tunnels and civil engineering structures.

Water and waste treatments.

Dams, reservoirs, and spillway.

Chemical areas.

Irrigation canals, sea walls and culverts.

Types of rubber water stop

1. Common Rubber Waterstop

2. Swellable Rubber Waterstops/Hydrophilic Rubber Waterstop belt

3. Rubber Waterstop with Steel Side

Shapes of rubber water stop

1.Rubber water stop - dumbbell type

Dumbbell type water stops, with flat web section, are ideal for construction and

partial contraction joints with little or no movements.

2.Rubber water stop - center bulb type

Center bulb type water stop, as its name implies, features its center bulb which

makes it ideal for contraction and expansion joints including high lateral,

transverse and shear movements. Meanwhile, it is perfect for withstanding the

subsidence of the joints.

As your request, other types including ribbed type, splitting type, base type or

capping type can be made to your order.

Processing procedures of rubber water stop

raw materials---1st pressing---2nd Pressing & cutting---3rd inner hose shaping

with the model---4th inner hose frozening(-19°C)---5th weaving/Twining for

several times(as request)---6th wrapping---7th vulcanization for 40-50 mins--

-8th unwrapping---9th model extrusion---10th testing---11th packaging---12th

finished products

Installation of rubber water stop

Most popular way of the placement of the water stop seal is tied to the steel

frame works or small eyelet by means of small wires, certain metal clamps

made to grip the water stop seal to keep it in proper position. Our water stops

are profiles based on specially formulated plasticized PVC compound, which

are designed to meet specific requirement of building industry. It is essential

that a device is used against potential risk of discomfiture that tends to be

caused in concrete structure following climatic, geo-disturbances and frictional

impasse which result in expansion or contraction in concrete structure. And the

expansion or contraction results in leakage/seepage of water exposing the

structure to bring the risk of cracks or dismemberment

Contact us if you need more details on Rubber Waterstop. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Stop、Rubber Water Stop. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water Stop Series > Rubber Water Stop